Home – ZAKS

April 10, 2020 2021-08-21 12:31Home – ZAKS

Shop by Categories

Best selling items

Test

SMC Make Air Cylinder Part No CDA2D50-200Z

AMC Make ABS Body Table Top Scale T2 Series Weighing Scale

₹0.50 – ₹3,421.00 18% GST Extra ( As Applicable )SMC Make Plug in / Plug Lead Single Unit, Part No VVQ5000-25A-1

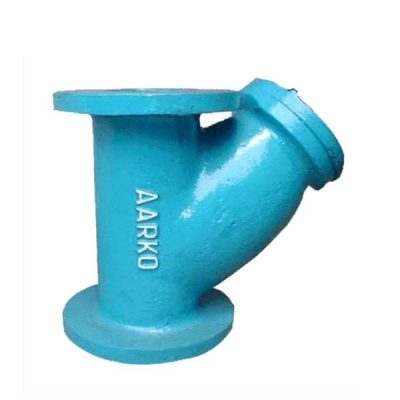

Aarko Make Flange Type T Strainer For Water Meter

₹2,040.00 – ₹36,780.00 18% GST Extra ( As Applicable )Baumer 50mm Bottom Pressure Gauge (AA-C2)

Metravi make Digital Anemometer Model No AVM-03

Industrial Stem Type Thermometer Mercury Filled

Work inquiries

Call us

Open hours

9:30 AM to 6:30 PM

Top Stories: Brand Directory.

MOST SEARCHED FOR ON ZAKS INSTRUMENTS PVT. LTD.: Pressure Instruments & Friendly Useable Temperature Instruments/ Flow Instruments/ Reliable Prices OF RTD Thermocouple/ ZAKS INSTRUMENTS PVT. LTD COVID-19 / ZAKS INSTRUMENTS PVT. LTD Insurance/ ZAKS INSTRUMENTS PVT. LTD Super/ ZAKS INSTRUMENTS PVT. LTD Help centre/ ZAKS INSTRUMENTS PVT. LTD Track Order/ ZAKS INSTRUMENTS PVT. LTD Manage Order/ ZAKS INSTRUMENTS PVT. LTD Return Order/

Categories: Pressure Gauge: Wika, Baumer, Feibig, H-Guru / Temperature Gauge: Wika, Baumer, H-Guru / Pressure Switch: Indfos, Switzer, Danfoss / Temperature Switch: Indfos /

Pressure Transmitter– Wika, Baumer, Honeywell, Dawyer / Valve- Solenoid Valve, hand Shut Off Valve, Indfos, Rotex, SMC / Level Switch– Baumer, SBEM /

Water Meter– Aquamet, Kranti / Weighing Scale– AMC, Kohinoor / RTD Thermocouple- ZIPL. / Compressor- compare / Limit Switch– Honey well / Flow Switch– Honey well /

Digital Multi Meter- Metravi / Regulator- Precision Regulator SMC / Cylinder- ISO Cylinder SMC / Controller- Speed Controller SMC / Fittings- SMC

BEST SELLING ON Zaks Instruments Pvt. Ltd: Wika Make Pressure Gauge & Temperature Gauge, Baumer Make Pressure Gauge & Temperature Gauge, Wika Make Pressure Transmitter, Indfos Make Pressure Switch & Solenoid Valve, Baumer Make Level switch, Aquamet Make Water Meter, AMC Make Weighing Scale, ZIPL Make RTD Thermocouple, compare Make Compressor.